Embracing only a small fraction of the total workforce, the sector nevertheless is responsible for an abundance of workplace injuries and illnesses that are proportionally higher than in other sectors. This is because manufacturing workers are exposed to the hazards of heavy machinery, hazardous materials, and other toxic substances on a daily basis.

They are the primary necessary tools for production, but at the same time, they are always there to remind people of the potential for accidents, ranging from mild to very severe ones. Additionally, individuals working with solvents, lubricants, and other chemicals in their projects may experience skin burns, rashes, and respiratory issues.

For example, workers who work with solvents, lubricants, or other chemicals not only encounter the risks of burns, but they also develop rashes and respiratory problems.

People operating heavy machines at work may face the danger of injuries from minor bruises to puncture wounds to amputation.

Good news, all this can be prevented by ongoing safety training

.

What is Ongoing Safety Training?

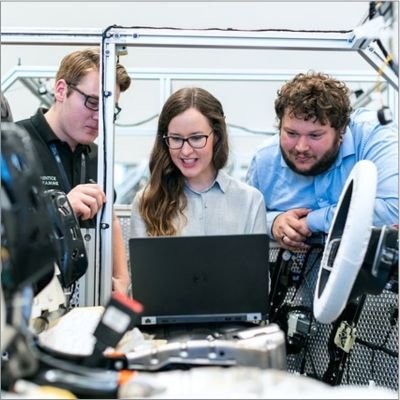

Ongoing safety training plays a fundamental role in every manufacturing operation. It is not a static process where training is given once, initially, and then forgotten.

It refers to continuous education and skill-building activities designed to ensure employees are up-to-date with safety protocols and best practices. It helps mitigate risks and maintain a safe working environment over time.

Safety training is, without a doubt, the first and most crucial aspect of your business, as it ensures that you do not harm your employees. Without a doubt, you should protect human life from anything that can happen there. There is no two ways about it. Securing life and ensuring the safety of your staff are always paramount.

Why is Safety Important in Manufacturing?

In 2019, the manufacturing industry recorded 846,700 injuries, accounting for 6.6 cases per 100 full-time workers, or 15% of all nonfatal injuries and illnesses in the private sector. Health and safety measures should always run alongside production activities in any manufacturing company. However, there is more to reinforcing health and safety policies than just protecting employees and complying with legal requirements.

Far too often, handicraft industries have viewed health and safety programs as a time drain and a waste of resources, and have prioritised productivity, quality, and cost-effectiveness over them. And here lies the paradox: by not safeguarding the employee, they are jeopardising exactly those business objectives.

The real truth? Health and safety are not competing interests; they are the very engine of success. Erecting an environment where considerate treatment of individuals in the cleaner is given the forefront creates the most significant returns in productivity, ensuring consistent quality, and cutting down on manufacturing costs. This is inarguably a win-win situation for both people and businesses, resulting in increased profits.

How to Implement Ongoing Safety Training in a Manufacturing Company

1. Evaluate Training Needs

Prior to the introduction of the trainee, the most important step is to make a very precise examination of the area where the risk is expressed and to carefully reach the company’s specific needs.

2. Create a Personal Training Program

Prepare training courses that are made to help the employees trace the line of the company’s and the industry’s specific needs. The modules should also take into account the risk that employees are exposed to.

3. Utilize Interactive Forms of Teaching

Utilize interactive methods of teaching, such as simulations, workshops, and e-learning modules, to enable employees to be involved and to provide an avenue for learning.

4. Keep Training Regular

No single safety training is enough for a safe environment. Keep continuous training on regular schedules to familiarize your employees with new practices and regulations.

5. Track and Improve Regularly

When each training session is over, feedback should be obtained from employees, and the program should be assessed for its effectiveness. Use the findings to make adjustments as you go along.

Benefits of Implementing Ongoing Safety Training

1. Reduction of Accidents and Injuries

Furthermore, effective workplace safety training enables workers to recognize danger and minimize it to a great extent, thus significantly enhancing the chances of accidents and injuries occurring in the workplace.

2. Regulatory Compliance

Moreover, safety training guarantees that all workers are familiar with the existing safety regulations and standards and that no one will fail to meet them, thus reducing the risk of being fined or penalized.

3. Improved Productivity

Employees who have undergone professional training are able to handle their work faster and more safely, hence the integral result is higher productivity.

4. Promotion of a Safety Culture

Regular safety training efficiently enables the creation and support of a work environment that is characterized by the absence of dangers.

Types of Safety Training for Employees

Induction training

New employees are taken through induction training to assist them in settling into the new working environment and activities.

This induction training will provide the new employees with a sketch of the organisation and the services that it offers.

It will help the employees to orient themselves with the new workplace, people, and processes.

The following are some of the issues you need to cover in induction training:

- workplace orientation

- emergency and fire safety measures

- first aid

- health and safety (e.g. risk assessment or accident reporting procedure)

- welfare facilities

- safe use of tools, machinery, and equipment used in the workplace

- risk assessments

- storage or maintenance of personal protective equipment

Refresher Training

Refresher training is imparted to the employees under the presumption that the skills that they possess are outdated or obsolete. This may be due to the fact that technology has improved,or it may be due to the fact that people have a tendency to forget.

The workers might be lax with safety measures, which might result in errors or failure. This is why it is necessary to update the knowledge and skills of the employees.

Toolbox Training

Toolbox talk is an informal safety meeting in the workplace. They are supposed to convey important safety messages to the employees. The discussions will assist in health and safety talks and will enhance a good safety culture in the organisation.

The discussions concern various safety issues associated with specific workplace activities. To give an example, you may use them to cope with:

- hazards

- safe systems of work

- risk assessments

- training needs

- health and safety news

- incidents and accident investigation news

- new equipment

The discussions may be in person, during shift change, scheduled huddles or a brief presentation. They are mostly kept brief and may be conducted by managers, supervisors or even other colleagues in the workplace.

Final Thoughts

Ongoing safety training is an essential investment for any manufacturing company, as it directly impacts both employee well-being and business performance. By prioritizing safety through continuous education and training, companies can prevent incidents, comply with regulations, and create a work environment that fosters productivity and morale.

As industries continue to evolve, the need for regular and updated safety training becomes even more crucial. Investing in Ongoing Safety Training is a clear win for both employees and the business, creating a sustainable and safe workplace for all.

FAQs

1. Why is ongoing safety training essential in manufacturing?

Continual safety training in manufacturing is crucial because it keeps your employees informed about the latest safety protocols, reduces workplace injuries, and ensures compliance with current regulations and industry guidelines. In addition, continual training promotes safer work efficiencies that support organizational productivity as well as workplace satisfaction.

2. How often should safety training be scheduled?

Safety training should be scheduled regularly, with continual safety training for employees. Many organizations tend to start with safety training, but allow periodic refresher training as new hazards and safety updates arise. Most safety training programs expect initial safety training, followed by refresher training on a periodic basis, generally annually, based on an organization’s hazards and regulatory updates.

3. What benefits are there to implementing continual safety training for your employees?

The benefits of implementing continual safety training for your employees include reducing workplace incidents and injuries, ensuring regulatory compliance, increasing productivity rates, improving product quality, enhancing employee morale, and decreasing indirect workplace costs such as costs associated with workplace compensation claims and/or legal disputes.

4. What safety training needs to be offered to manufacturing workers?

Manufacturing workers need to be offered different categories of safety training including: general workplace safety, machinery/equipment safety, hazardous materials safety, fire safety, ergonomics safety, job-specific safety, and continual refresher training for your workforce to remain current with safety practices and regulations.

Related Posts

16 August, 2025