This blog discusses how LMS platforms can revolutionise the safety training of factory employees, make them adhere to the industrial safety rules, and embed the critical safety points in the industry in the core of operations.

The Importance of Factory Safety

Factories are active places with loads of heavy machines, risky materials, and complex operations. Those risks are genuine: there can be injuries, diseases, and even deaths in case of industrial safety rules are not being seriously kept. In addition to the human cost, workplace accidents result in lost productivity, legal fines, and reputation loss for a business.

- The main aim is to protect the health and well-being of all employees.

- Appropriate training can reduce the chances of accidents and injuries in the long run.

- When the environment is safe, there will be fewer disruptions and morale will be boosted.

- The use of safety rules in the industry prevents unwanted fines and lawsuits.

- Safety helps companies attract higher-skilled staff and even retain them.

The Old Way of Safety Training

In traditional factories, safety training was based on face-to-face meetings, printed manuals and rare workshops. Although these approaches are valid, they commonly fail in the current high-paced, constantly changing industrial environment:

- Industrial safety rules might be understood differently by different trainers.

- Information overload and poor retention may be caused by long lectures and thick manuals.

- Records in paper form cause difficulty in checking who has undergone the training and who requires a reminder.

- Manual updates take time when new regulations or equipment modifications are involved.

LMS: A Revolution for Safety Training

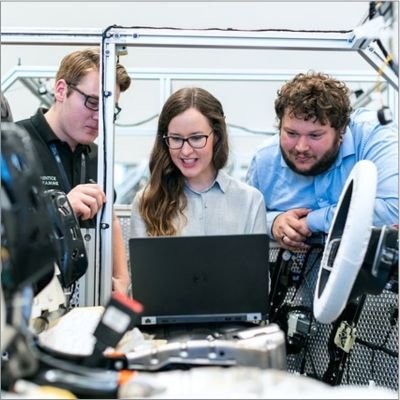

A Learning Management System (LMS) refers to an online platform which stores, distributes, and monitors training programs. Why an LMS? In the case of factories, LMS is more than a strategic tool that takes safety training to the next level.

How does LMS integrate Safety Points?

Centralised Content

With an LMS, all the safety training materials, whether it is a video, a manual, or an interactive course, can be stored in a single location. This is to make sure that all workers are aware of the latest safety points in the industry that they should observe according to their position.

Role-Oriented Training

Risks vary with different jobs. The LMS platforms help the factories assign certain training modules to groups so that each employee has access to the industrial safety rules that incorporate their duties when it comes to daily operations.

Interactive Learning

Modern LMS platforms employ multimedia, simulation, and scenario-based learning to ensure safety rules in the industry are memorable. As an example, employees could walk a virtual factory floor, identifying areas of danger and learning how to respond to unsafe situations in a risk-free setting.

Ongoing Improvement

LMS administrators are capable of updating the training content rapidly whenever regulations change or new equipment is launched. This flexibility keeps the safety points in the industry up-to-date and useful.

Tracking in Real-time

Supervisors will be able to see in real-time training completion dates, quiz scores and renewal of certificates. Automated reminders help prevent losing any important retraining and keep the factory within the industrial safety rules.

Safety Rules Every Worker Should Abide By

To realise the worth of LMS-based training, it is necessary to get an understanding of the basic safety regulations operating in the industry, which should be adhered to by all factory workers:

- Personal Protective Equipment (PPE): You are not allowed to work without helmets, gloves, goggles, and masks.

- Clean the Work Areas: Avoid slips, trips, and falls by ensuring the working areas are clean.

- Report Hazards Instantly: Report something that you find unsafe instantly, or repair it when it is within your capacity.

- Lockout/Tagout Process: Factories must lock out machines when doing maintenance.

- Use Tools and Machines Safely: Operate the tools you have been trained for and allowed to use.

- Check Equipment: Before using the equipment, check it to make sure it is not damaged or undergoing any malfunction.

- Learn Emergency Procedures: Learn to evacuate routes, fire extinguishers and first aid locations.

- Avoid Loose Clothing and Jewellery: Eliminate the chances of being tangled by moving machines.

- Store Materials: Materials, including flammables and other hazardous materials, should be stored safely.

- Take Part In Safety Drills: Safety drills make emergencies perfect.

Such industrial safety rules form the basis of a safe factory environment. Having them embedded into LMS modules guarantees that all workers not only learn them but also comprehend why they are essential.

Sticking with Safety Training

Engagement is a frequent issue during safety training. The LMS platforms provide innovative ways of ensuring that safety points in the industry can connect with the workers:

- Microlearning: Short modules that can be made a part of our busy lives and enhance retention.

- Gamification: With points, badges and leaderboards, we can make learning a friendly game.

- Video Content: Visuals are easier to memorise as compared to written words.

- Scenario-Based Learning: Real-life simulations enable workers to rehearse the decision-making process in a risk-free setting.

- Smartphone and Tablet-based Training: Training can be done using mobile smartphones and tablets.

LMS’s Impact in the Real World

The factories already using LMS platforms to train in relation to safety are reporting remarkable outcomes:

- Firms experience a 20 to 30 per cent reduction in the number of accidents in the workplace upon application of LMS-based safety training.

- Automated tracking helps to ensure that at least 90 per cent workers take the required training in time.

- Digital training saves up to half of the costs of traditional methods.

- Employees value that they are appreciated and that there is security, so job satisfaction and turnover are reduced.

Fighting Challenges

Though the benefits are obvious, proper integration of the LMS system demands careful planning:

- Determine the particular risks and gaps in training at your factory.

- Implement modules to match your industrial safety rules and devices.

- Ask the people to give feedback to make the training relevant and interesting.

- Based on the LMS analytics, improve them and revise the content regularly.

- Ensure that safety is not about checking the box, everyone is expected to keep things safe.

The Potential of Safety Training

The role of LMS in safety training will continue to increase as factories adopt the digital transformation. The available technologies such as augmented reality (AR), virtual reality (VR), etc. are coming in place to recreate some complex situations and introduce the workers to the workplace where the safety points should be addressed even prior to going to the factory floor.

Besides, with the changing regulations and the types of risks, LMS platforms will be more capable of adapting promptly so that the safety rules in the industry will always be on the central stage of the mind of every worker.

Final Thoughts

Safety is not a policy, it is a way of thinking and an everyday activity. When it comes to manufacturing, where everything is critical and every action is valuable, good safety training is something that is not up to date. Using the potential of LMS applications, factories are capable of providing engaging and modern training, which inculcates industrial safety rules and safety points in the daily routine of each worker.

The outcome? Fewer accidents, increased productivity, and a working population that feels satisfied knowing they are good and well taken care of. Ultimately, investing in LMS-driven safety training is not really a matter of compliance, but rather a matter of creating a better, safer, and more successful future for all those who end up on the factory floor.

Related Posts

15 August, 2025